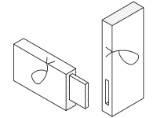

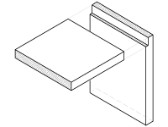

Producing Joints with the Router | Some of the common woodworking joints can be produced with Safety when the router is used in the plunge mode with the aid of the template guides. |

|

|

|

|

|

|

|

|

|

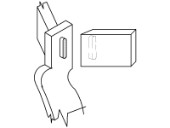

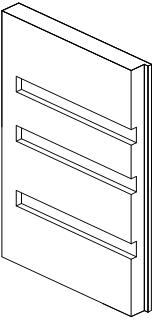

The above joint was used to insert the arm rest into the back legs of the dining room chairs without the need for any screws or nails. | Soon to be released is a 'Super Jig' capable of producing 14 different Joints Feb 2011 |

News flash.

The Super Jig is now available

Feb 2012