| "There is a need to re-think how the router can be used". When designing a project we must consider how the material is to be held secure. |

Jig Holder - Jigs - and Templates

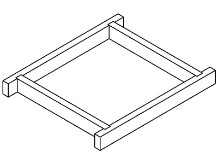

Jig holders are prepared to hold the material to be cut and the template securely in position. Each Jig is designed to suit the size of the material to be cut. Some are long and narrow others are small rectangular or square Jig Holder. Jig holder is a simple box. The box is 400 x 300 x 40mm (internal dimensions.) the purpose of the Jig holder is to hold the jig that will hold material secure, and also position the template correctly for each process. The material can either be placed in position and fixed to the base of the Jig holder or attached to a Jig that is situated in the base of the jig holder. This will depend on the thickness of the material to be used for the project | Making or Buying Jigs. Jigs and templates are not always available for purchase for the project you are producing, and therefore it will be necessary to design and construct you own.

Jigs will not only introduce greater SAFETY AWARENESS it will also improve the standard of finish on many projects that can be completed with a router. With a firm understanding of the use of the router with jigs and templates may eliminate the need to purchase other speciallity power tools. |

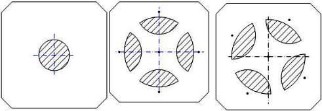

Making the Jig It could be argued that more time is spent making the jigs and templates than actually routing the project. Sample: Elliptical picture frame Illustrated; Making one template will allow you to produce a number of the same article all exactly the same size. Producing a second template which can also act as a Jig in the base of the Jig Holder. The rebate for the glass and photograph can be routered before the material is removed from the Jig Holder leaving the external edge to be completed with the router in the router table. |

|

12 Sided Clock

Constructing your own jigs and templates will enable you to accomplish a greater variety of projects.

|

Templates are produced from 9-12mm MDF with the necessary 'cut-out' to produce the final shape of the project (12 Sided clock) with greater safety awareness Note; In this instance it is possible to combine the three templates into one which is a saving of material |

With a firm understanding on how the template guides are used will introduce you to new projects that can be achieved with greater accuracy and safety: Download the PDF file above for more information and view more projects produced with the aid of the template Guides and the construction of Jigs and Templates.

There are many books available on ROUTING giving details of routers, router bits, safety precautions and simple routing applications and techniques, unfortunately there has been little published illustrating the use of the guides and the construction of simple jigs that can be produced in your own workshop. Woodworking magazines and lately ‘ROUTER MAGAZINES’ are available for purchase to keep up to date with what is new on the market, and the availability of manufactured jigs to make routing easier.